Rotary Vibrating Screen

Product Description for XZS Rotary Vibrating Screen

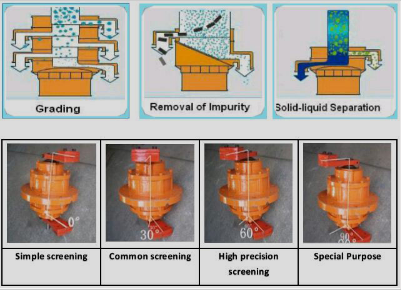

XZS Rotary vibrating screen also called rotary vibro sifter,round vibratory sieve.It can filter the liquid like waste water.Removing the impurity in the material,such as milk powder,rice,corn etc.Separating or grading the mixed powder into different size that you requirement.

Layers Show

Working Principle

XZS rotary vibrating screen uses a vertical motor as the excitation source. The upper and lower ends of the motor are installed with eccentric weights, which convert the rotary motion of the motor into three-dimensional motion of horizontal, vertical and inclined, and then transmit this motion to the screen surface. . Adjusting the phase angle of the upper and lower ends can change the movement track of the material on the screen surface.

Features

1. Can be used with single or multilayer screen mesh.

2. Automatic discharge of materials, continuous operation.

3. No dead corner of parts, easy rinse thoroughly and disinfection.

4. High screening precision, high efficiency, suitable for any powder, grain and mucus materials.

5. New grid structure, long service life of screen cloth, only 3-5min for screen mesh replacement.

6. Small volume, less space occupation, easy to move,360 degree adjustment of discharge opening.

7. Fully enclosed structure, no flying dust, no liquid leakage, no blocking of mesh opening, screen can reach 500 meshes, and filter can reach 5 um.

Details specification

| Model | XZS rotary vibrating screen |

| Machine Diameter | 400mm-2000mm |

|

Motor Power |

0.25KW-3kw |

| Mesh hole | 2-500 mesh(More than 200 mesh,can use ultrasonic system ) |

| Machine Material | All stainless steel 304/316L,All carbon steel,Contact material part with sus304/316L |

| Layers | 1-6 layer(1-4 layer has best screening efficiency) |

| Auxiliary Means | Ultrasonic system/universal wheel /Viewport/ON OR OFF switch/Iron remover/Feeding hopper etc |

| HS Code | 8479820000 |

| Applications | Kinds of powder(particle)/Liquid/Solids and liquids |

| Voltages | Single Phase or Three Phase 110v-660V |

Structure

Parameter Sheet

|

Model |

Diameter(mm) |

Feeding Size(mm) |

Frequency(RPM) |

Layers |

Power(kw) |

|

XZS-400 |

400 |

<10 |

1500 |

1-5 |

0.25 |

|

XZS-600 |

600 |

<10 |

1500 |

1-5 |

0.55 |

|

XZS-800 |

800 |

<15 |

1500 |

1-5 |

0.75 |

|

XZS-1000 |

1000 |

<20 |

1500 |

1-5 |

1.1 |

|

XZS-1200 |

1200 |

<20 |

1500 |

1-5 |

1.5 |

|

XZS-1500 |

1500 |

<30 |

1500 |

1-5 |

2.2 |

|

XZS-1800 |

1800 |

<30 |

1500 |

1-5 |

2.2 |

|

XZS-2000 |

2000 |

<30 |

1500 |

1-5 |

3 |

Applications

1) Chemical industry: resin, pigment, cosmetic, coatings, Chinese medicine powder

2) Food industry: sugar powder, starch, salt, rice noodle, milk powder, egg powder, sauce, syrup

3) Metallurgy, Mine industry: aluminum powered, copper powder, ore alloy powder, welding rod powder

4) Medicinal industry: all kinds of medicine

5) Waste treatment: disposed oil, disposed water, disposed dye waste water, active carbon

How to confirm the model

1).If you have ever used the machine,Pls give me the model directly.

2).If you never used this machine or you wanna us to recommend,Pls give me the information as below.

a).The material you wanna to sieve.

b).The capacity(Tons/Hour) that you require?

c).The layers of the machine?And the mesh size of each layer.

d).Your local voltages

e).The special requirement?

Cases

Customer Feedbacks