Pigment is a powdery material used for coloring. Generally ,only the three primary colors of red, blue and yellow can be used to adjust all the other colors. However, the purity of the adjusted colors is always not high enough. Therefore, pigment manufacturers need to produce various colors. Brightness color pigments can meet various needs. According to the requirements of pigments for fineness and purity, ultrasonic vibrating sieves need to be sieved to meet this requirement.

1,Ultrasonic vibrating screen has higher screening capacity and screening accuracy. Compared with ordinary rotary vibrating screen, the accuracy can be increased by 1-70%, and the output can be increased by 0.5-10 times.

2,It can solve the screening problems of materials with strong adsorption, easy agglomeration, high static electricity and light specific gravity

3,It can work continuously for 24 hours, control power box and transducer not need cooling

4,The transducer and the screen are connected by screws, which is easy to disassemble and clean

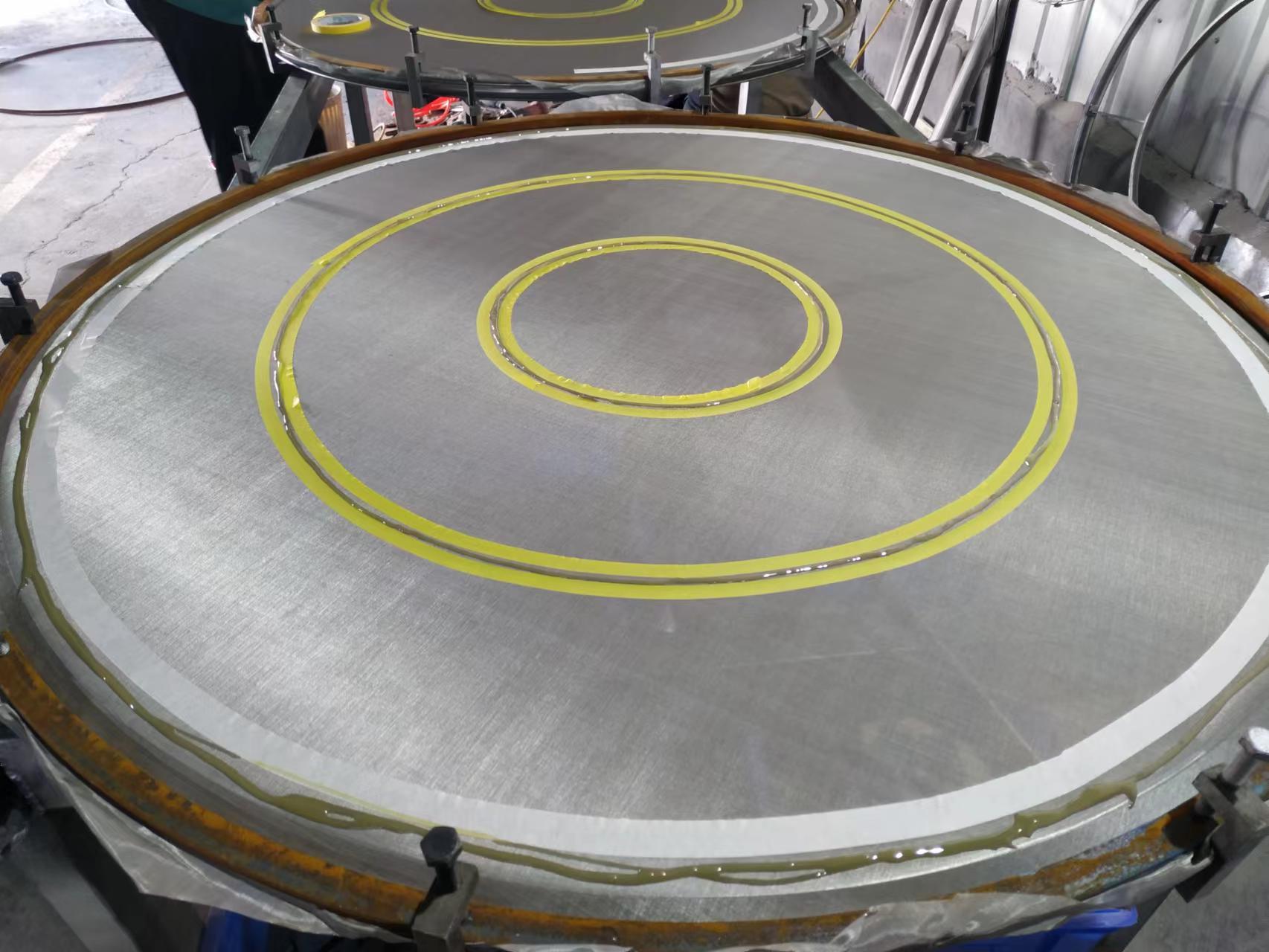

5,Separate structure, with resonance ring, good effect, long screen life

6,It can screen materials within 20 microns, and can filter liquids within 10 microns

7,Not need the rubber balls to clean the screen mesh, no recontamination caused by rubber wear

8,The layout of the special ultrasonic screen frame has no dead ends, the force is symmetrical, and the replacement is convenient.

Post time: Sep-20-2022