Seals are mainly used in rotary vibrating screens, linear vibrating screens, circular shakers and square shakers. They are one of the indispensable accessories in the vibrating screen industry. They are mainly used on vibrating screen frames and dust covers. The connection between the sealed vibrating screen frames prevents the raw material fluid or solid particles from leaking from adjacent joint surfaces, prevents external impurities such as dust and water from invading the internal parts of the machine equipment, and at the same time reduces the impact of the vibrating screen on the screen during vibration. destructive power of the frame. It is an indispensable wearing part in the vibrating screen.

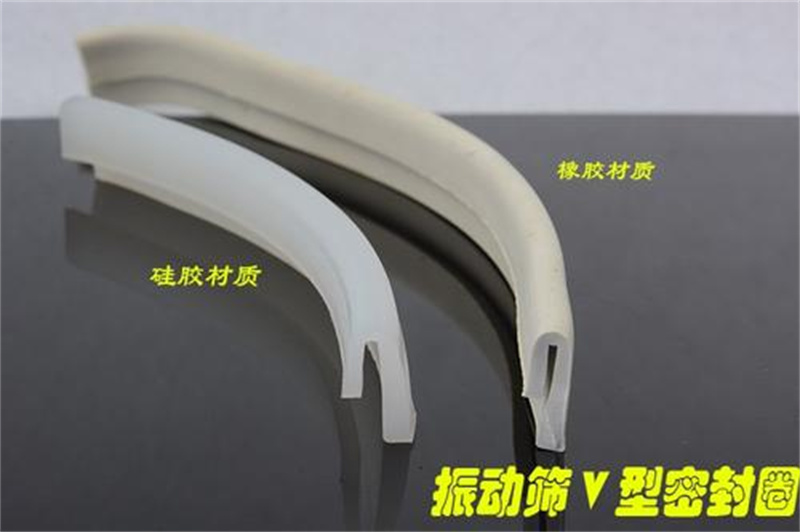

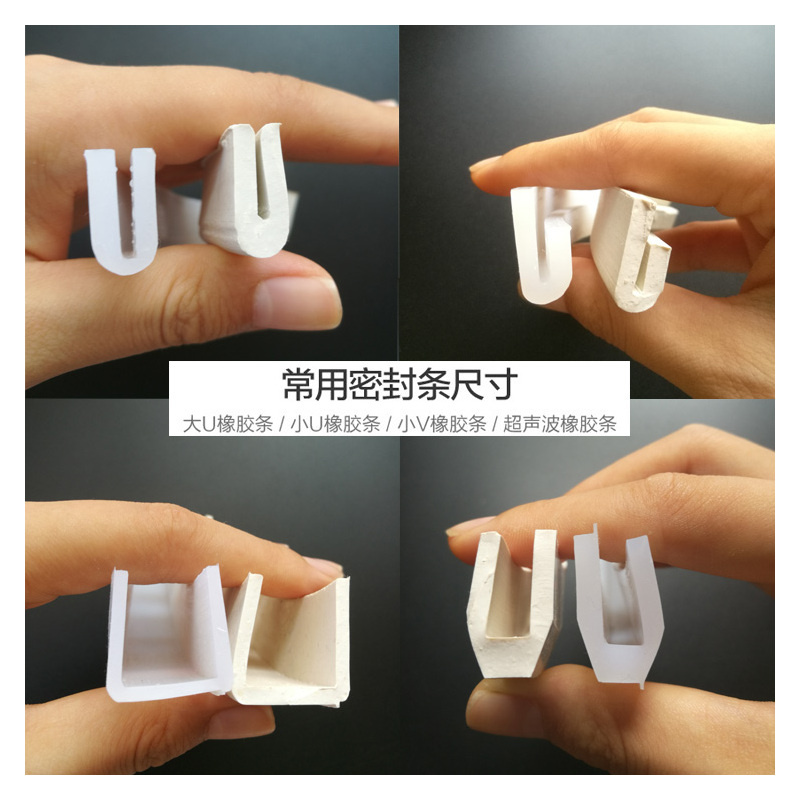

Commonly used rubber seals according to material: rubber and food-grade silica gel. Food-grade silica gel strips are mostly used in industries with special requirements such as food industry and pharmaceutical. , it can be divided into U-shaped and V-shaped. The V-shaped sealing ring is mainly used between the dust cover and the grid and between the grid and the lower cylinder. The U-shaped sealing ring is used between the two screen frame.

Standard vibrating screens are equipped with rubber sealing rings and rubber balls unless customers have special requirements. Silicone rubber rings and bouncing balls are mainly used for materials with special characteristics, such as high temperature, oily, corrosive and other materials.

Xinxiang Hongda Vibrating Equipment Co.,ltd reminds you: when purchasing a vibrating screen, you should also pay attention to choosing a sealing ring that is more suitable for the material you are screening, otherwise it is likely to increase the cost of wearing parts of the equipment.

Post time: Feb-05-2023