There are many classifications of vibrating screen, according to the trajectory of the material can be divided into circular vibrating screen and linear screen, both of which are commonly used in daily production of screening equipment. Fine screening machine is less used in the production of breaking and grinding, and here we do not make too much comparison. Circular vibrating screen and linear vibrating screen style and structure composition is not essentially different, the material is through the screen surface vibration and get the purpose of screening, but the different vibration trajectory will directly affect the purpose of screening.

Linear Vibrating Screen

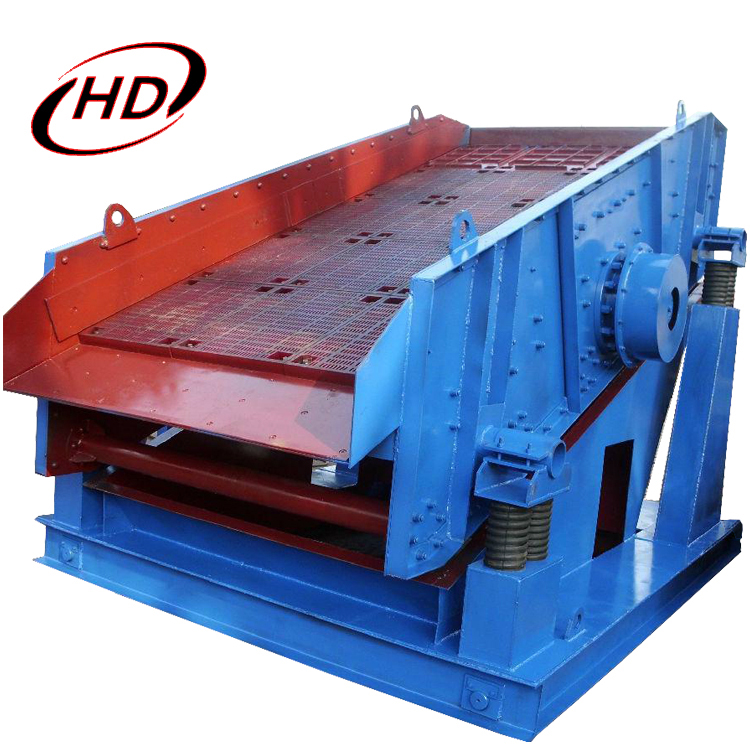

Circular vibrating screen(YK Series Vibrating screen)

Working principle

➤ Circular vibrating screen

The electric motor is driven by v-belt to make the eccentric block of exciter rotate at high speed, which generates great centrifugal inertia force and excites the screen box to produce circular motion of certain amplitude, and the material on the screen is subjected to the impulse transmitted by the screen box on the inclined screen surface and produces continuous throwing motion, and the material meets the screen surface in the process of making the particles smaller than the screen hole penetrate the screen, so as to realize the classification.

Vibrating screen mesh

➤ Linear vibrating screen

Using vibration motor excitation as the vibration source, the material is thrown up on the screen, while making linear motion forward. The material enters the inlet of the screening machine evenly from the feeder, and produces several specifications of the top and bottom of the screen through the multi-layer screen, which are discharged from their respective outlets.

Difference comparison

➤ Plugging hole phenomenon

The material of circular vibrating screen moves in a parabolic circle on the screen surface, so that the material is dispersed as much as possible to improve the material bouncing force, and the material stuck in the screen hole can also jump out, reducing the phenomenon of hole blocking.

Installation arrangement

Because of the small inclination of the screen surface, the height of the screen is reduced, which is convenient for the process arrangement.

➤ Screen inclination angle

According to the particle size of the material, the circular vibrating screen can change the inclination angle of the screen surface, so as to change the movement speed of the material along the screen surface and improve the processing capacity of the screen machine. Generally speaking, the inclination angle of the screen surface in the production of linear vibrating screen is small.

Vibrating screen mesh

➤ Material

In general, the circular vibrating screen is made with thicker plates and the box is made of manganese steel, which is to resist the impact of the material during the screening process. Linear vibrating screen is mainly made of light plate or stainless steel plate.

➤ Application field

Circular vibrating screen mainly screens materials with high specific gravity, large particles and high hardness, which is widely used in mining industry such as mine, coal and quarry. Linear screen mainly screens materials with fine particles, light specific gravity and low hardness, mainly dry powder, fine granular or micronized materials, and is usually widely used in food, building materials and other industries.

➤ Handling capacity

For the circular vibrating screen, because the exciter is arranged above the center of gravity of the screen box, so the elliptical long axis of the two ends of the screen box into the lower eight, and the upper end of the elliptical long axis of the feed end faces the direction of discharge, which is conducive to the rapid dispersion of materials, while the upper end of the elliptical long axis of the discharge end is against the direction of discharge, reducing the speed of material movement, which is conducive to difficult to sieve materials through the screen, and the circular arc-shaped screen surface and increase the effective area of the screen machine, so as to improve its processing capacity.

In addition, for difficult to screen materials, circular vibrating screen can make the spindle turn over, so that the direction of vibration is opposite to the direction of material movement, and the speed of material movement along the screen surface is reduced (in the case of the same screen surface inclination and spindle speed), in order to improve the screening efficiency.

➤ Environmental protection

Linear vibrating screen can take a fully closed structure, no dust overflow, more conducive to environmental protection.

Post time: May-23-2022