U Type Screw Conveyor

Product Description for LS U type Screw Conveyor

LS U type Screw Conveyor adopts the structure of "u"-shaped machine groove, lower screw assembly and fixed installation. The u-shaped groove is connected by segmented flanges, which is easy to replace and maintain the inner bushing. The LS U-type screw conveyor is suitable for horizontal or small inclination conveying, and the inclination angle does not exceed 30°. It can be fed or discharged at a single point, and can also be fed or discharged at multiple points. It is suitable for occasions with large dust and environmental requirements. The upper part of the conveyor is equipped with a rain-proof cover, which has good sealing performance. The conveying process is basically closed transportation, which can effectively reduce the leakage of indoor odor or the entry of external dust.

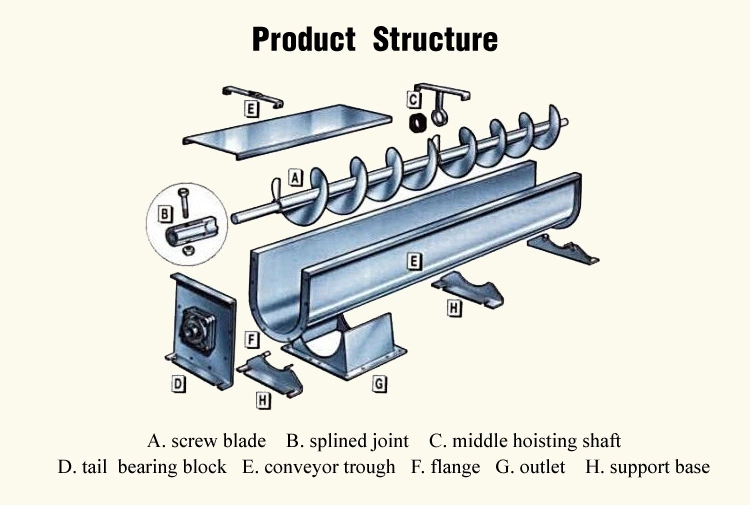

The LS U type screw conveyor is mainly composed of the driving device, the head assembly, the casing, the screw body, the tank lining, the feeding port, the discharging port, the cover (if necessary), the base and so on.

Applications

Working Principle

The rotating shaft of the LS U type screw conveyor is welded with a screw blade. When working, the screw blade will generate a forward power generated by the rotation, which will force the material to move forward to complete the transportation. The reason why the material does not rotate with the blade in this process is because one is The gravity of the material itself is the frictional resistance generated by the inner shell of the equipment to the material.

Classification of LS U type screw conveyor

1. According to the structure:

U-shaped shaftless screw conveyor: granular/powder material, wet/paste material, semi-fluid/viscous material, easy to entangle/easy to block material, material with special hygiene requirements.

U-Shaft Screw Conveyor: Materials that are not easy to stick and have certain friction. There are certain requirements for the wear resistance of the screw conveyor.

2. According to the material:

Carbon steel U type screw conveyor: It is mainly used in industries such as cement, coal, stone, etc., which wear a lot and have no special requirements

Stainless steel U type screw conveyor: mainly used in industries such as grain, chemical industry, food and other industries that have requirements on the conveying environment, with high cleanliness and no pollution to materials.

LS U type Screw Conveyor is suitable for

1).the fluidic or low-fluidity materials, like milk powder, Albumen powder, rice powder, coffee powder, solid drink, condiment, white sugar, dextrose, food additive, fodder, pharmaceuticals, agriculture pesticide, and so on.

2).Cement,fine sand,calcium carbonate clay powder, pulverized coal, cement, sand, grain, small piece of coal , cobble, and cast iron filings, etc.

3).Waster water,sludge,garbage etc.

Parameter Sheet

| Model | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 |

| Screw diameter(mm) | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 |

| Screw pitch(mm) | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 | 560 |

| Rotate speed(r/min) | 60 | 50 | 50 | 50 | 50 | 50 | 50 | 45 | 35 |

| Delivery value

(φ=0.33m³/h) |

7.6 | 11 | 22 | 36.4 | 66.1 | 93.1 | 160 | 223 | 304 |

| Pd1=10m(kw) Power | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 | 5.1 | 8.6 | 12 | 16 |

| Pd1=30m(kw) Power | 2.8 | 3.2 | 5.3 | 8.4 | 11 | 15.3 | 25.9 | 36 | 48 |

How to confirming the model

1).The capacity(Tons/Hour) that you require?

2).The conveying distance or the conveyor length?

3).The conveying angle?

4).Whats the material to be convey?

5).Other special requirement,like hopper,wheels etc.