Rectangular Gyratory Vibrating Screen

Product Description for DZSF Linear Vibrating Screen

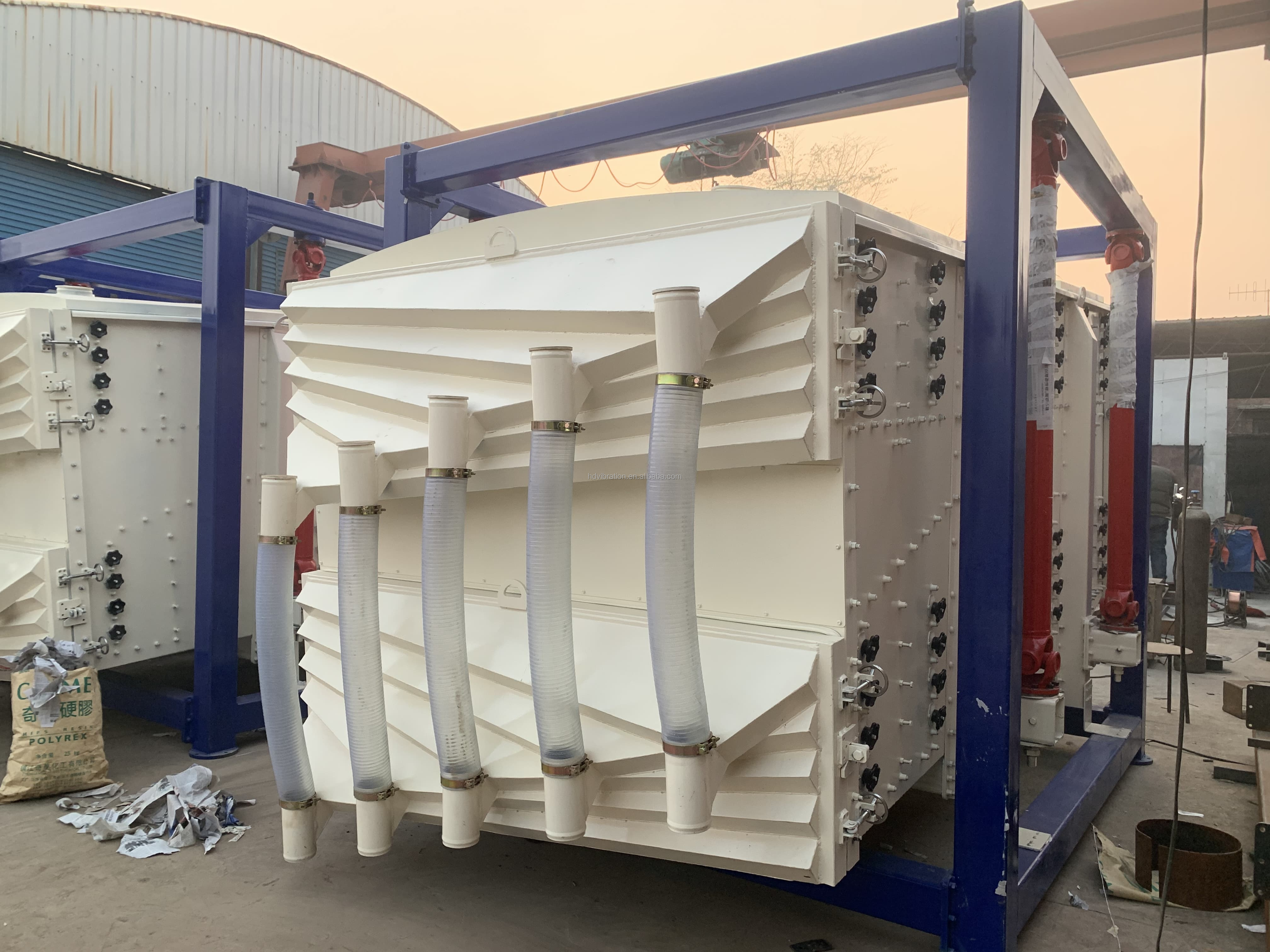

FXS Square Gyratory Screener is a high-efficiency screening equipment specially designed for high precision and large capacity output.It is widely used in sand, mining, chemical, non-ferrous metals, food, quartz sand, abrasive and other industry and fields.The screen mesh frame and the screen mesh and bouncing balls installation method adopt quick open design and easy to install, so the installation is very convenient. Usually two feed inlet channel available. 8-layer design,can be divided into 9 grades at one time.

Details Display

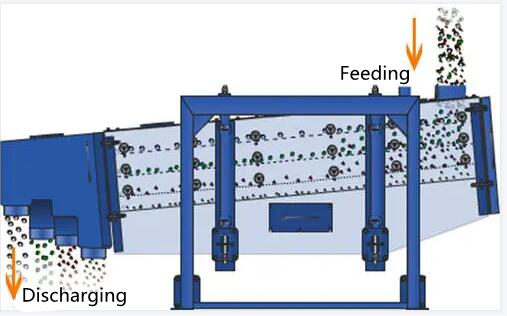

Working Principle of FXS Square Gyratory Screener

FXS Square Gyratory Screener adopts to rotex technology,we also call it Rotex screen, which obviously improves the distribution of the

material, thus it will enhance the screening efficiency and the effective utilization of the screen surface, also reduce the

powder content of the final material .This design is totally enclosed without dust pollution,it not only improve the operation

environment but also reduce the dynamic ratio and foundation load effectively.

Application

FXS Square Gyratory Screener can be used in chemical industry, new materials, metallurgy, metal powder, mineral powder, food, salt, sugar, abrasive, feed and other industries. Especially suitable for quartz sand, fracturing sand, glass sand, white sugar, plate sand, ceramsite sand, recarburizer, pearl sand, microbeads and other materials.

Parameter Sheet

|

Model |

Sieve Size (mm) |

Power (KW) |

Inclination (Degree) |

Layers |

Rate of frequency (r/min) |

Screen Box movement distance(mm) |

|

FXS1030 |

1000*3000 |

3 |

5 |

1-6 |

180-264 |

25-60 |

|

FXS1036 |

1000*3600 |

3 |

5 |

1-6 |

180-264 |

25-60 |

|

FXS1230 |

1200*3000 |

4 |

5 |

1-6 |

180-264 |

25-60 |

|

FXS1236 |

1200*3600 |

4 |

5 |

1-6 |

180-264 |

25-60 |

|

FXS1530 |

1500*3000 |

5.5 |

5 |

1-6 |

180-264 |

25-60 |

|

FXS1536 |

1500*3600 |

5.5 |

5 |

1-6 |

180-264 |

25-60 |

|

FXS1830 |

1800*3000 |

7.5 |

5 |

1-6 |

180-264 |

25-60 |

|

FXS1836 |

1800*3600 |

7.5 |

5 |

1-6 |

180-264 |

25-60 |

How to confirming the model

1.)If you have ever used the machine,Pls give me the model directly.

2.)If you never used this machine or you wanna us to recommend,Pls give me the information as below.

2.1)The material you wanna to sieve.

2.2).The capacity(Tons/Hour) that you require?

2.3)The layers of the machine?And the mesh size of each layer.

2.4)The special requirement?

Packaged and Shipping

Packaging: Usually pack the small model in wooden case or as your requirement.

Delivery Time: We promise that the standard model spends 7-10 working days.No-standard model 15-20 spends working days.