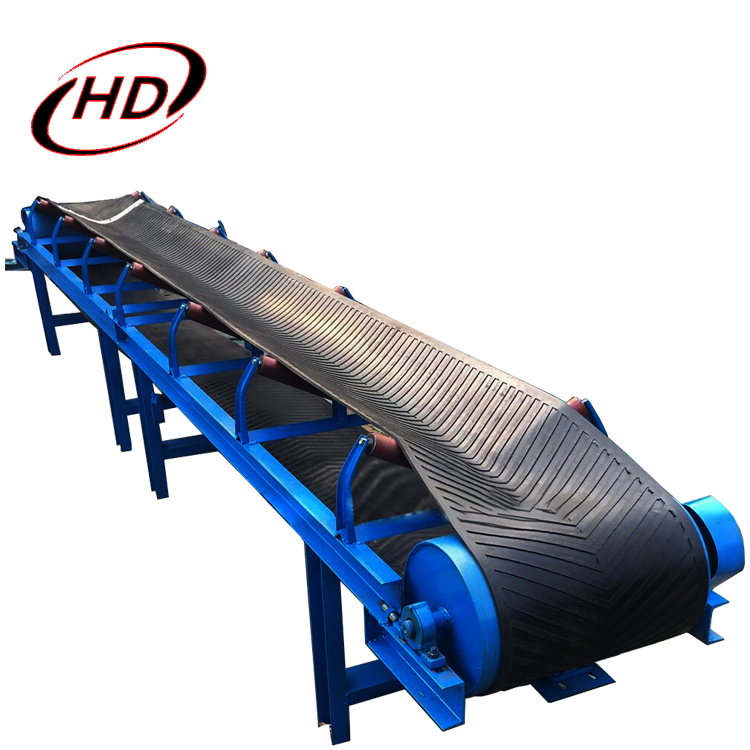

100% Original Material Handling Belt Conveyor - TD75 Series Fixed Belt Conveyor – Hongda

100% Original Material Handling Belt Conveyor - TD75 Series Fixed Belt Conveyor – Hongda Detail:

Applications

TD75 Fixed Belt Conveyor is suitable for conveying powdery, granular and small-sized low-abrasive materials and bagged materials that are easy to pick up, such as coal, gravel, Sand, cement, fertilizer, grain, etc. The belt conveyor can be used in the range of ambient temperature -20℃ to +40℃, and the temperature of the material being sent is less than 60℃. The length and assembly form of the machine can be determined according to the user’s requirements. The transmission can be either an electric drum or a drive device with a drive frame.

Parameter Sheet

How to confirming the model

Product detail pictures:

Related Product Guide:

No matter new shopper or old customer, We believe in very long expression and dependable relationship for 100% Original Material Handling Belt Conveyor - TD75 Series Fixed Belt Conveyor – Hongda , The product will supply to all over the world, such as: Gambia, Macedonia, Philadelphia, Honest to every customers are our requested! First-class serve, best quality, best price and fastest delivery date is our advantage! Give every customers good serve is our tenet! This makes our company get the favour of customers and support! Welcome all over the world customers send us enquiry and looking forward your good co-operation !Please your inquiry for more details or request for dealership in selected regions.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.